In the Midwest, reducing and decarbonizing energy use in the residential and commercial sectors will be vital for navigating the energy transition, and many of our states and utilities are taking steps in the right direction. However, this progress makes it easy to overlook another, lagging sector in the Midwest: the industrial sector.

As the center of the nation’s manufacturing and industry, the Midwest and the “Rust Belt” are almost synonymous. Of the thirteen states in the Midwest Energy Efficiency Alliance’s (MEEA) region, eight are in the top half of national rankings for industrial electricity use; nine are in the top half for total industrial energy. Given the scale of the energy consumed by the industrial sector and the emission intensity of that consumption, the Midwest’s energy and carbon issues depend inextricably on increasing industrial energy efficiency in the region. The industrial sector is where the Midwest needs to focus and redouble our energy efficiency efforts.

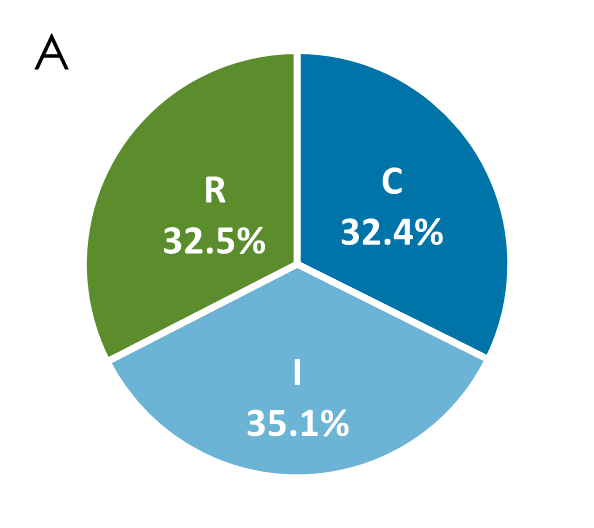

Despite this need, the Midwest has not been achieving industrial energy efficiency at the same rate as we see in other sectors. In fact, it is not even close. Using available federal data, we can see that industrial sector energy efficiency is often left unaddressed by utility customer-funded energy efficiency programs. The region’s downward trends were exacerbated by the pandemic and the gutting of clean energy in Ohio by the scandal-ridden House Bill 6 (2019). Industrial sector energy efficiency in the Midwest is now at its lowest point of the last decade, despite comprising more than a third of the region’s total electricity consumption. Reported electricity savings from the industrial sector in the Midwest dropped 44% between 2020 and 2021 for the region and represent a paltry tenth percent of electricity sales to that sector. We cannot perform a similar analysis of natural gas energy efficiency, because comparable federal gas savings data does not exist, but state-level data and experience suggest that number is even lower.

|  |

Figure 1. A. Electricity consumption by customer sector in the Midwest. B. Electric energy efficiency in the Midwest, as a percentage of total electricity sales by sector. (source: EIA-861)

There are substantial policy barriers standing in the way of utility customer-funded industrial energy efficiency. First, most energy efficiency policies in the region only apply to investor-owned utilities. However, 23% of industrial electricity load in the Midwest, 78 million MWh, is served by publicly-owned utilities – cooperative and municipal utilities, public power districts and a small amount of federal ownership. Unregulated public utilities are required to provide some energy efficiency in a few Midwest states, but for the most part they are left out of energy efficiency legislation.

The biggest policy barrier to industrial energy efficiency, however, is the opt-out. Opt-out policies allow the largest energy users to notify their utility that they do not wish to participate in or contribute to energy efficiency portfolios. In Indiana, opt-outs have removed 70-80% of the commercial and industrial load from efficiency portfolios. In Ohio, under proposed legislation that would restore some energy efficiency for the state’s electric utilities, large mercantile customers are automatically opted-out and would need to proactively opt-in to participate. Proponents of opt-outs say that “if it makes economic sense to save energy, then industrial customers will do so on their own,” but evidence has long shown that the market alone will not drive energy efficiency adoption without policies that promote EE and utility programs that push adoption rates. Opt-outs, which originally applied only to industrial energy efficiency, are trickling into other sectors as well – Iowa has a cost-effectiveness requirement in policy that could trigger an all-customer opt out, and the previously mentioned Ohio legislation also includes an opt-out for residential and small business customers.

There is enormous potential to turn around industrial energy efficiency in the Midwest. Industrial heat pumps are reaching into high-temperature process heating that previously was only possible using fossil fuels. Broad training initiatives are being developed by MEEA and our partners to advance industrial workforce energy training across facilities in multiple states. And there is growing recognition that combined heat and power (CHP) can play a major role as a cleaner distributed energy resource for industrial customers. Our recent paper for the ACEEE Summer Study on Energy Efficiency in Industry found that if the most energy-intensive manufacturing in the Midwest deployed CHP at the current average level of deployment in those industries, then there is potential to double the megawatts of installed CHP and reduce total regional carbon emissions by 4.4%.

We interviewed Cliff Haefke, Director of the Energy Resources Center at the University of Illinois at Chicago, Director of the U.S. DOE Midwest and Central Combined Heat and Power Technical Assistance Partnerships, Assistant Director of UIC’s DOE Industrial Assessment Center, President of the Midwest Cogeneration Association, and MEEA Board Member, about the role of CHP in decarbonizing industrial energy.

How does CHP contribute to emission reduction from the large energy user segment?

CLIFF: Combined heat and power (CHP) is the most efficient way to generate electric power and thermal energy with total energy efficiencies often exceeding 80%.

CHP is a fuel-flexible generating resource that can use a variety of fuels, including, but not limited to, natural gas, propane, renewable fuels, low-carbon waste fuels, hydrogen where available, and will be ready to use higher levels of biogas, renewable natural gas (RNG) and hydrogen in the future.

A large energy user has the potential to reduce more emissions when utilizing CHP technologies due to CHP’s higher overall efficiencies than when compared to a large energy user otherwise receiving their energy from separate heat and power (SHP) sources of generated electricity from a local power plant and thermal energy via onsite boilers.

How does CHP help grid resilience?

CLIFF: CHP is an on-demand and dispatchable energy generating resource, with the ability to operate on a variety of fuels, providing flexible, long duration resiliency, and operational reliability capabilities. Due to its dispatchability and its high capacity factors of 90% and greater, CHP can be a reliable source of energy that is connected to the grid.

CHP can also provide grid support that is needed as more and different types of distributed energy resources (DERs) come online. There is potential for CHP in providing stability and reliability for the electric power system through ramping capability, frequency response and voltage control.

All DERs are subject to disaster events to some extent, some more than others. Distributed systems with islanding capabilities and the right supporting technologies can enhance resilience and provide uninterrupted power during emergencies. CHP systems provide a controllable generation source that can be paired with batteries to deliver optimized resilient power. Incorporating these with variable DERs like wind and solar can complement the disaster response while reducing GHGs and alleviating stress on the grid.

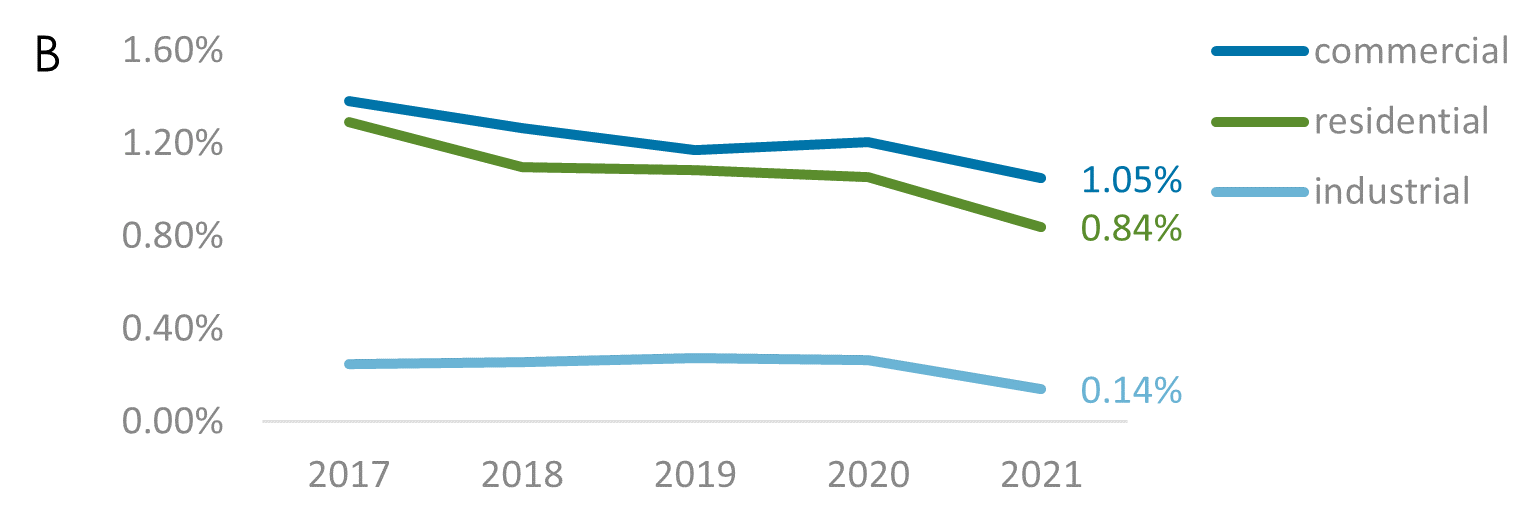

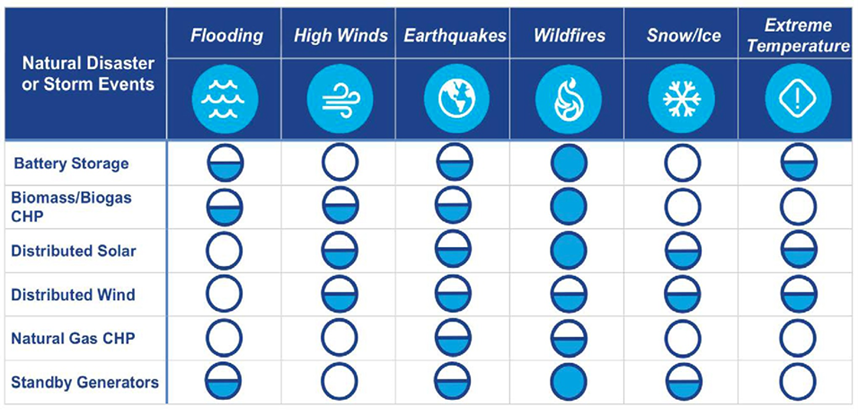

The Department of Energy compared CHP and other DERs’ vulnerability to weather events in a Better Buildings Issue Brief. They show the likelihood of experiencing fuel supply interruption, damage to equipment, performance limitations or planned/forced shutdowns across different types of emergency events.

|  |

Figure 2: Matrix of DER Vulnerability to Weather Events (Source: U.S. DOE Better Buildings Issue Brief)

How does CHP react to the grid getting cleaner – what happens when it isn’t lowering net carbon anymore?

CLIFF: CHP provides reliable heat and power with high efficiency and lower emissions than current generation. The emission benefits and energy savings come from replacing separate thermal systems and purchased power with a single integrated system at the point of use. Compared to separate production of heat and power, with an average system efficiency of about 50%, clean CHP systems can have overall energy efficiencies of 65-85%.

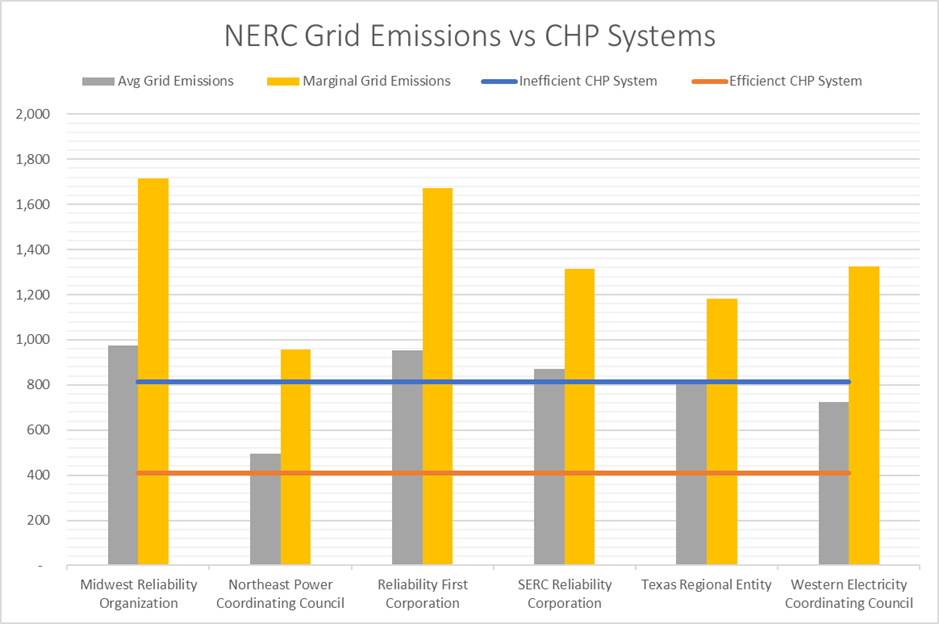

In the near- to mid-term, CHP is cleaner than the marginal grid emissions from fossil-fueled generation in most of the country. Systems installed today should be built to have emissions lower than the grid for the duration of their useful life, including planning for retrofit to cleaner fuel sources where possible. CHP prime movers that avoid fossil fuels entirely, such as nuclear, renewable and synthetic fuels and other renewables further support the use of CHP in a fully decarbonized energy economy.

CHP systems that use digester and biogases have been deployed for a long time, and as availability of RNG increases, more systems will be configured to operate on it. Hydrogen produced using nuclear energy is another strategy for decarbonizing CHP. Manufacturers are working on engines and turbines that operate on high percentages of RNG and hydrogen fuels to meet future increases in those fuels. Systems that operate efficiently and with low criteria pollutant emission using these advanced fuels can be a long-term path for decarbonization of industrial thermal processes that have thus far resisted electrification and can provide resilience and reliability for critical operations.

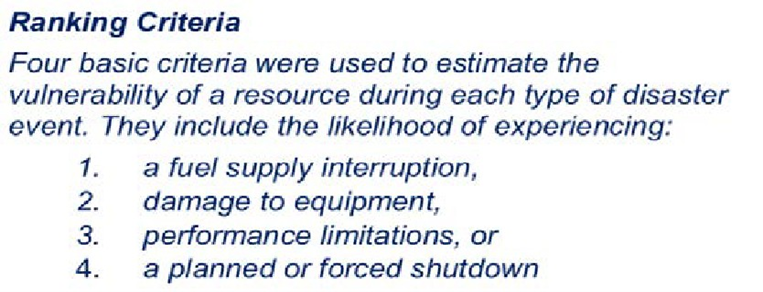

Today, a clean and efficient CHP system, even operating on natural gas, has higher net electricity efficiency than state-of-the-art marginal natural gas generation, has lower net GHG emissions than marginal natural gas generation, and can meet marginal grid loads more efficiently and with less CO2 emissions. Efficient natural gas CHP systems today compare very favorably to the average and marginal grid emissions of the various regional transmission organization (RTO) regions, as shown below.

Figure 3: NERC Grid Emissions vs CHP Systems (Source: Entropy Research, LLC, 10/5/21)

Industrial buildings are generally very energy intensive and difficult to decarbonize. However, energy efficiency can be a powerful tool in reducing energy consumption and emissions. Whether it comes from technological process improvements, workforce training on energy issues or cleaner customer-sited distributed resources, increased energy efficiency will help large users control energy costs and remain competitive as the energy systems in the Midwest change to meet decarbonization goals. The Midwest’s industrial market is primed for substantial energy savings, but it will take investment and political will to address the barriers that are holding back those gains in the region. MEEA will continue to work toward and advocate for these tools and opportunities for industrial efficiency to gain traction and create energy savings for customers across the Midwest.

This blog was released in partnership with other Regional Energy Efficiency Organizations (REEOs), Northeast Energy Efficiency Partnerships (NEEP), Southeast Energy Efficiency Alliance (SEEA), Southwest Energy Efficiency Project (SWEEP) and South-central Partnership for Energy Efficiency as a Resource (SPEER), to highlight prominent issues impacting each respective region.