The Alliance for Industrial Efficiency (AIE) recently released a new report analyzing the energy efficiency and sustainability goals of the nation’s 160 largest manufacturing companies. The report identifies the states with the most facilities with these goals, and four Midwest states—Ohio, Illinois, Michigan and Indiana—made the top 10.

What’s clear from AIE’s report is that even in states where energy efficiency policies have been rolled back, many prudent businesses have maintained their commitment to energy efficiency through internal goals.

Energy-Intensive Manufacturing Remains a Pillar of the Midwest Economy

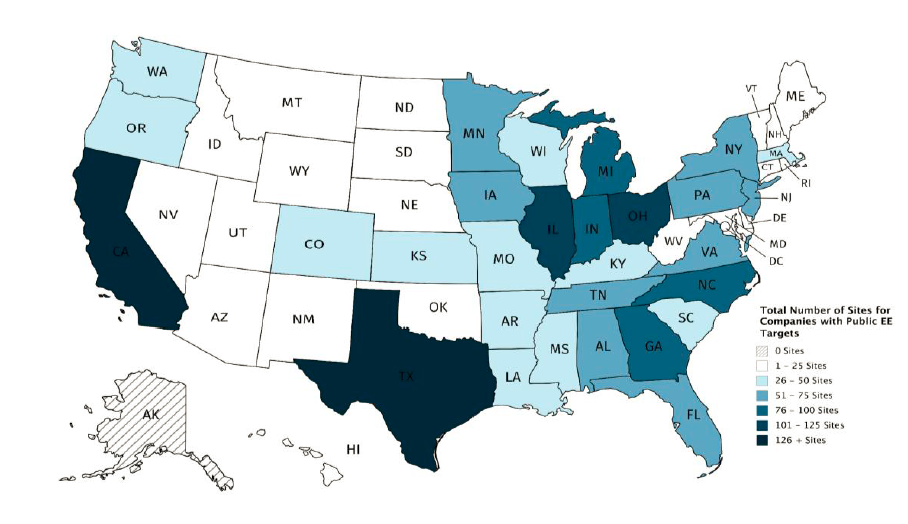

The Midwest accounts for 32% of the nation’s total industrial electricity consumption and manufacturing represents a substantial share of the region’s Gross Domestic Product (GDP). Despite this significant energy use, statewide policies are increasingly weakening industrial energy efficiency requirements, budgets and options in the Midwest. As these policies relax, industrial customers have an opportunity to take a leadership role to realize the system-wide benefits of energy efficiency. According to AIE, the Midwest contains over 500 manufacturing facilities with company-wide energy efficiency policies.

Indiana Manufacturers are Saving Millions through Efficiency

For ArcelorMittal and Cummins facilities in Indiana, the business case for efficiency is clear. Since 2006, ArcelorMittal has saved more than $257 million annually on energy costs, and Cummins has saved about $50 million over the same period.

Indiana’s statewide energy efficiency requirements were eliminated in 2014 and nearly 70% of eligible industrial customers have opted out of paying into energy efficiency programs, but companies are stepping up and taking advantage of utility programs.

How Can We Encourage Manufacturers to Adopt Integral Targets?

These manufacturers exemplify corporate leadership through on-going energy efficiency efforts in the manufacturing sector. While statewide policies may change, increasing instances of corporate sustainability leadership can still lead to incremental resource conservation, despite a recent pattern of policy rollbacks.

AIE’s report offers policy recommendations to manufacturing companies, state policymakers and utilities to promote the value of these internal sustainability and clean energy policies.

AIE recommends that policymakers can foster energy efficiency goals by:

- Creating incentives and revenue recovery mechanisms for utilities

- Removing barriers to industrial energy efficiency that make it harder for customers to participate

- Fostering dialogues between utilities and large customers

AIE also recommends utilities provide robust energy efficiency offerings to industrial customers so manufacturers can meet their internal targets cost-effectively.

MEEA’s Role in Industrial Energy Efficiency

As a nonpartisan convener, MEEA is well positioned to facilitate conversations between industrial customers, utilities and policymakers, and to provide state-specific best practices. At MEEA, we continue to identify resources and opportunities to assist utilities in engaging and educating large energy users on energy efficiency benefits.

We will continue to shine a light on these positive stories, while examining barriers and how they can be overcome through outreach and education.

If you have a story of corporate leadership, related research needs or questions about these issues, we want to hear from you. Contact Senior Policy Manager Nick Dreher.

Upcoming Webinar Series

Committed to Savings: Setting and Achieving Energy Efficiency Targets in the Manufacturing Sector

September 6 & 13

In this two-part webinar series, take a deeper dive on this important research. You'll hear from Alliance for Industrial Efficiency experts and the energy-savers profiled, including Cummins and ArcelorMittal.